Arevo will display the “world’s first” 3D-printed carbon fibre unibody production bike frame in the stand of manufacturing partner Oechsler AG (Messe Friedrichshafen – hall A1 – 508) at Eurobike 2019.

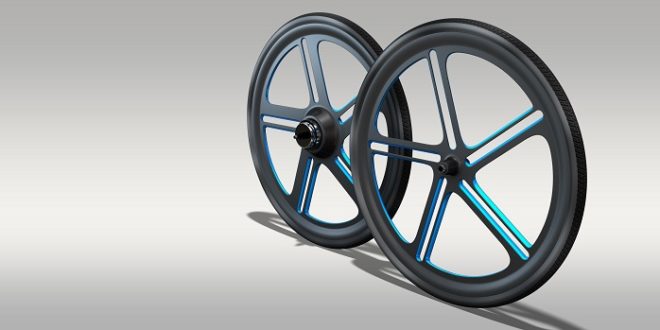

The company will also display the “world’s first” 3D printed thermoplastic rim, designed by Eurobike Gold Award-winning industrial designer Bill Stephens of StudioWest.

It is also offering demonstration rides on an e-bike featuring this frame and material, similar to that announced earlier this year at the Sea Otter Classic in California. Further, the company will announce next week a new e-bike frame design and a new customer for it. This customer, a bike industry leader based in the Netherlands, will display this new e-bike in the Eurobike exhibition hall.

Its ‘Arevo DNA’ technology features patented software algorithms enabling generative design techniques, free-motion robotics for ‘True 3D’ construction and direct energy deposition for virtually void-free construction all optimised for anisotropic composite materials. The Arevo DNA AM process takes the design and final manufacture of a bike frame from 18 months to just a few days at a significant reduction in product development costs.

Stephens has worked closely with Arevo for more than a year now and will elaborate upon these concepts in a presentation entitled ‘3D Printing Carbon Fiber Frames for Production’ on 5th September, 11:00 to 11:45 am.

“Arevo DNA offers a new paradigm for product designers, it forever changes how we can design and build anything,” said Stephens. “This technology allows us to push design boundaries in a way that was impossible until now. Arevo is changing the paradigm to ‘Manufacturing for Design’.”

BikeBiz Bicycle and cycling retail news

BikeBiz Bicycle and cycling retail news